Circular Economy

Area: Design, planning and building

Circular Economy (CE), also referred to as circularity, is a sustainability concept applied to various industries – including the built environment – which aims to improve the way products are made and consumed, and essentially to prevent the unnecessary destruction of resources. The CE idea is founded on the rejection of the current take-make-waste model and instead supports a system that is “restorative or regenerative by intention and design” (EMF, 2013, p.7). The European Commission defines CE as “a system which maintains the value of products, materials and resources in the economy for as long as possible and minimises the generation of waste” (EUR-Lex, 2021). CE builds upon concepts such as Cradle-to-Cradle (McDonough & Braungart, 2002) and The Performance Economy (Stahel, 2010). The term has recently grown in popularity, as evidenced in a study by Kirchherr et al., who identified 221 CE definitions, though the meaning of the term remains largely ambiguous (2023).

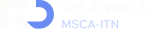

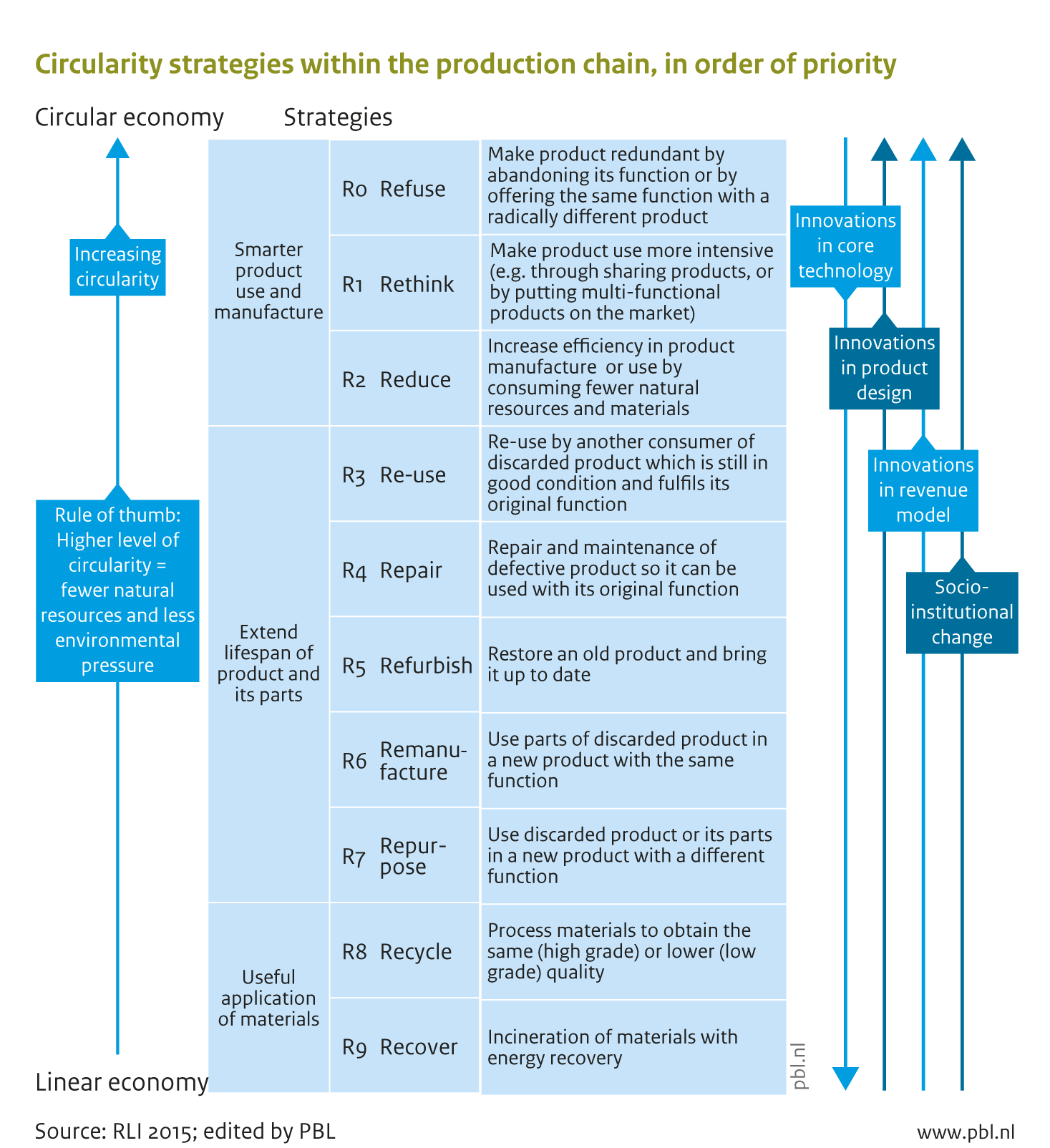

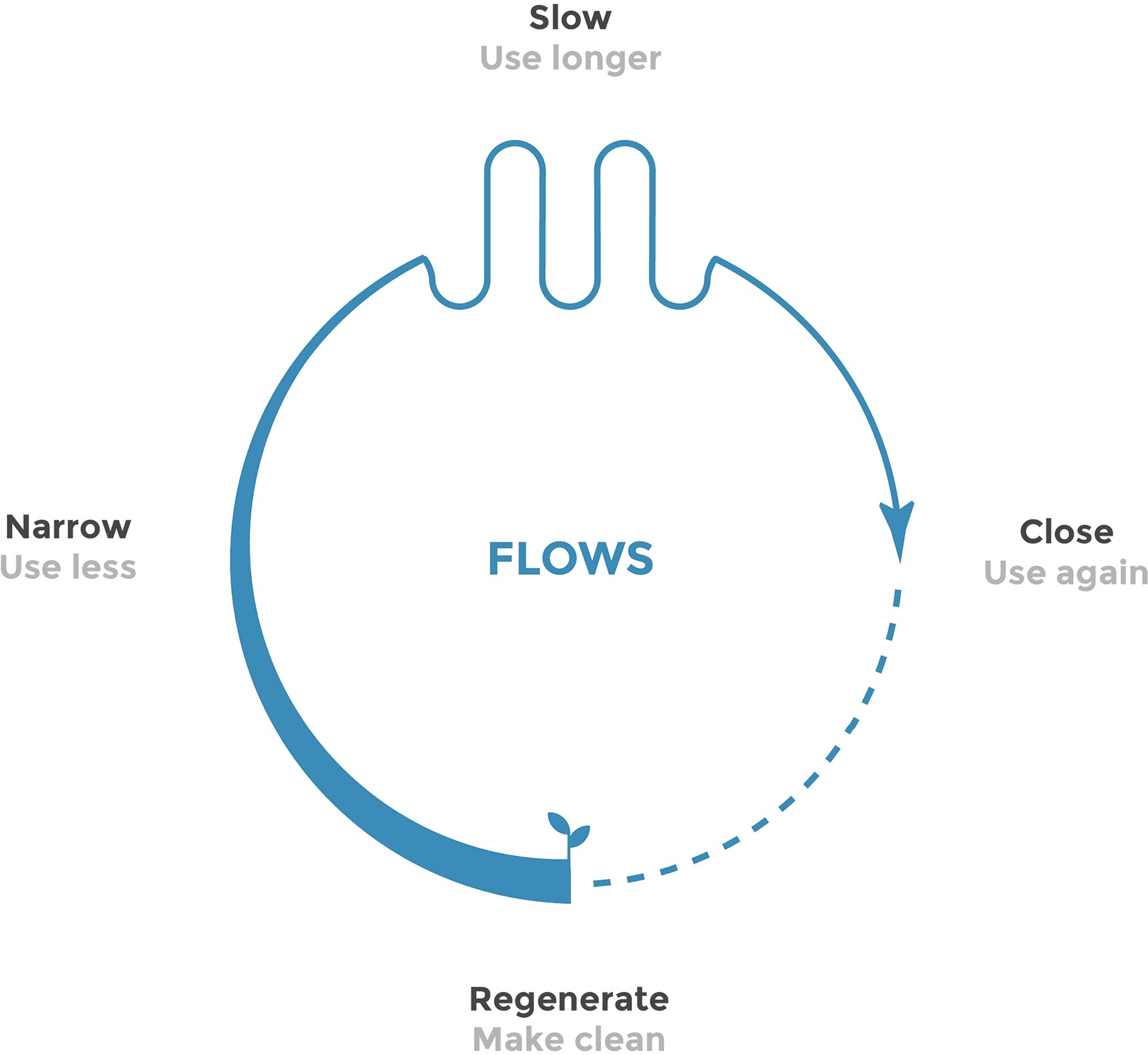

CE encompasses both design and business considerations to better ensure products are responsibly managed and retained at their highest value possible within the value chain, rather than being destroyed. Business strategies include shifting consumption from selling products to services; this can take the form of Product-as-as-Service models or take-back schemes (Tukker, 2015). Several prominent theoretical frameworks support the CE transition, these include the R-Ladder outlining a decision-making hierarchy (Potting et al., 2017), the Ellen MacArthur Foundation’s Butterfly diagram which distinguishes technological materials from biological materials (EMF, 2013), and Bocken et al.’s four strategies defining the need to close, slow, narrow, and regenerate resource loops (2016). Key circular construction approaches that facilitate circularity in a systematic way include design for disassembly and industrialised construction.

Several political instruments under the European Green Deal promote the progression towards a circular economy in buildings and housing, most notably the Circular Economy Action Plan (European Commission, 2020) and the Waste Framework Directive (EC, 2008). Despite these initiatives and the potential for the CE transition to improve both the environmental sustainability and affordability of housing, it is still in the early stages in Europe. This is largely due to building complexity, short-term financial barriers, and the persistence of common practices such as the extraction of raw materials and building demolition. However, several practical advancements that have been implemented include Circular Economy Statements within the London Plan (GLA, 2022), the Building Circularity Indicator (BCI) in the Netherlands (Alba Concepts, n.d.), and the Building Circularity Tool by OneClick LCA (n.d.).

References

Alba Concepts. (n.d.). Welkom bij BCI Gebouw. Retrieved May 29, 2024, from https://www.bcigebouw.nl/

Bocken, N. M. P., de Pauw, I., Bakker, C., & van der Grinten, B. (2016). Product design and business model strategies for a circular economy. Journal of Industrial and Production Engineering, 33(5), 308–320. https://doi.org/10.1080/21681015.2016.1172124

EC. (2008). Waste Framework Directive 2008/98/EC. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02008L0098-20180705

EMF. (2013). Towards the Circular Economy. https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an

EUR-Lex. (2021). Circular Economy. https://eur-lex.europa.eu/EN/legal-content/glossary/circular-economy.html#:~:text=A%20circular%20economy%20is%20a,minimises%20the%20generation%20of%20waste.

European Commission. (2020). First Circular Economy Action Plan. https://ec.europa.eu/environment/topics/circular-economy/first-circular-economy-action-plan_es

GLA. (2022). London Plan - Guidance Circular Economy Statements. www.london.gov.uk

Kirchherr, J., Yang, N.-H. N., Schulze-Spüntrup, F., Heerink, M. J., & Hartley, K. (2023). Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resources, Conservation and Recycling, 194, 107001. https://doi.org/10.1016/j.resconrec.2023.107001

McDonough, W., & Braungart, M. (2002). Cradle to Cradle: Remaking the Way We Make Things. North Point Press.

OneClick LCA. (n.d.). Measure circularity in construction. Retrieved May 29, 2024, from https://oneclicklca.com/software/design-construction/building-circularity

Potting, J., Hekkert, M., Worrell, E., & Hanemaaijer, A. (2017). Circular Economy: measuring innovation in the product chain.

Stahel, W. (2010). The performance economy (2nd ed.). Palgrave-MacMillan.

Tukker, A. (2015). Product services for a resource-efficient and circular economy - A review. Journal of Cleaner Production, 97, 76–91. https://doi.org/10.1016/j.jclepro.2013.11.049

Created on 30-09-2024 | Update on 23-10-2024

Related definitions

Design for Disassembly

Area: Design, planning and building

Created on 18-10-2023 | Update on 23-10-2024

Read more ->Industrialised Construction

Area: Design, planning and building

Created on 09-11-2023 | Update on 23-10-2024

Read more ->Life Cycle Assessment

Area: Design, planning and building

Created on 30-09-2024 | Update on 23-10-2024

Read more ->Related cases

WikiHouse: South Yorkshire Housing Association

Created on 16-10-2024